Replacing a mainspring in a watch is just about the most common repair that I make each week. I thought I would give you a bit more information as to how this is done.

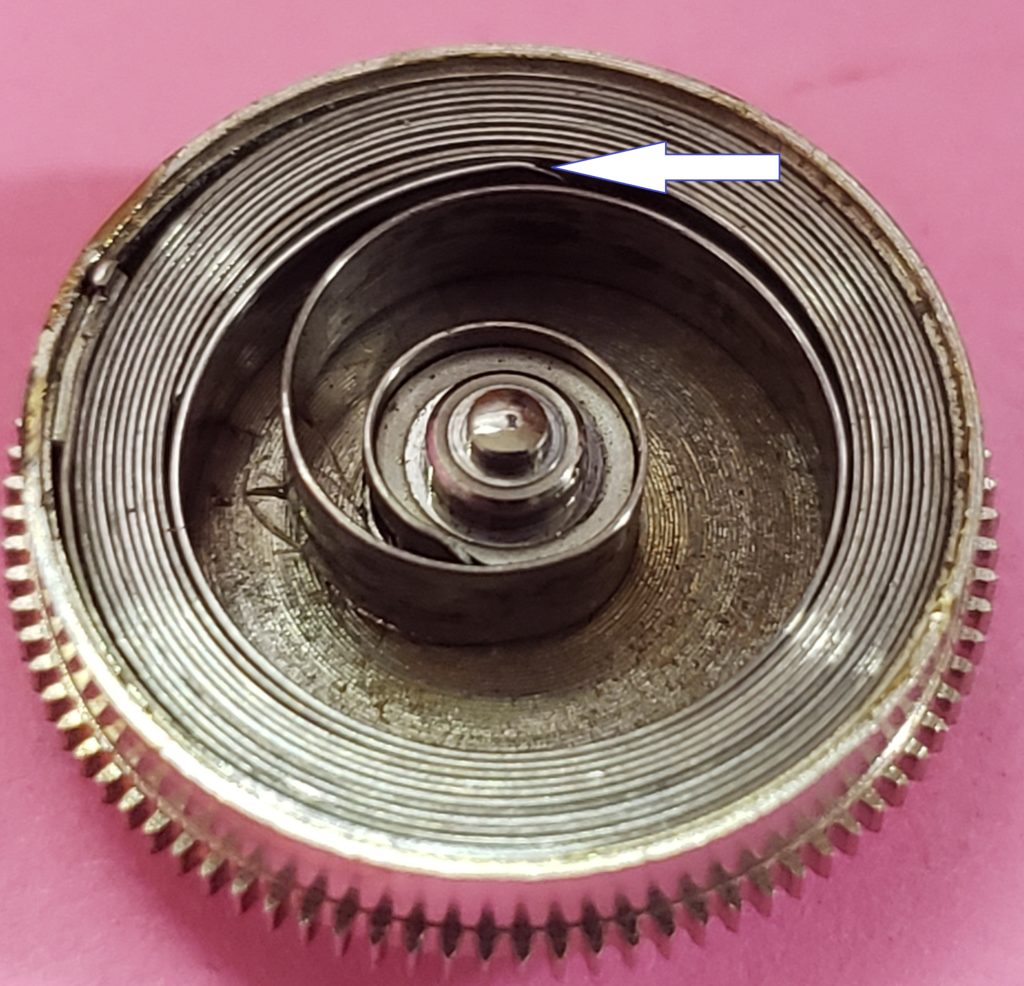

Here’s a Hamilton 992 with barrel cap off showing the break in the spring.

The spring will normally break at the center. That is where most of the stress is placed as it is wound and unwound.

This is the end of the mainspring. This Hamilton uses a “T” end spring. The two tips fit into the top and bottom holes in the barrel.

This is how the new spring is shipped from my supplier. In a “perfect world,” the spring is pushed into the empty mainspring barrel and the job is done.

This rarely works since I need to push the spring and have one of the ends perfectly hit the hole in the barrel.

When pushing it in fails then we will wind it in by hand. The spring is more than 12 inches long, very strong, and difficult to wind.

You will notice the nice “S” shape of the spring.

This is where years of practice comes in handy. I need to have one tip of the “T” end fit into the small hole in the barrel, wind it in without losing my grip which will send the barrel flying across the room!

New spring and barrel arbor in place.

Here’s a barrel cap back on. You will notice the small slot in the cap that matches up with the other end of the spring.

Sometimes the “T” end is a bit too wide, so you will notice that the last repair person has filed down the excess on the cap.

CHARLEY PHOTO OF THE WEEK: It’s getting cooler outside, so that means Charley is back sleeping on her bed in the workshop with all her pillows.