Today’s blog post will continue with the overhaul of a Rolex 3135 movement. We will go over the reassembly process, oiling and buffing. After the movement comes out of the cleaning machine, the parts are unpacked from the cleaning basket and the process starts. I normally make a quick check to see if all the parts that went into the machine, are also there when it came out. Sometimes parts “disappear” in the basket. A bit like when you do laundry and for some reason a sock is gone. The machine has been known to eat a small part or a screw!

The first part that is installed in the main plate is the center post:

After the center bridge is installed, the train wheels are put into place

Mainspring is oiled and barell cap ready to be installed

Train bridge is installed

A little oil on the train wheel pivots

Next the barell bridge

Barell top jewel oiled

Now we flip the movement over and begin work on the dial side and date.

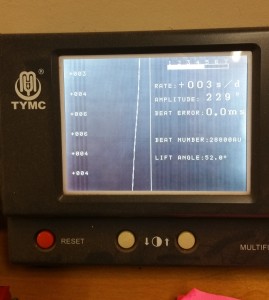

Date back together. Now on to the timing machine. Movement cleaned and running well on the timing machine. Rolex spec’s are -4 to plus 6 seconds a day. I normally shoot for 3-5 seconds fast. I always l regulate it fast, customers hate it when their watch is slow!

Movement cleaned and running well on the timing machine. Rolex spec’s are -4 to plus 6 seconds a day. I normally shoot for 3-5 seconds fast. I always l regulate it fast, customers hate it when their watch is slow!

Automatic unit is next to be oiled and put back together.

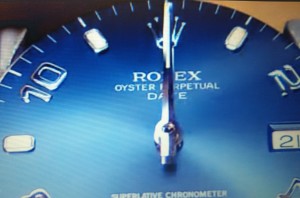

The movement is again flipped over and the dial and hands are installed. Here comes the tricky part, getting the hands set so that the date changes at 12:00. This normally takes a few trys before the hands pass inspection.

Case now needs some attention. Here is a before picture of the case side and dirty case tube.