Invented around 1974 and patented in 1980 by English watchmaker George Daniels the Co-axial escapement is a modification of the lever escapement. Considered by some to be one of the most significant horological advancements since the invention of the lever escapement, the co-axial escapement functions with a system of 3 pallets that separates the locking function from the impulse, avoiding the sliding friction of the lever escapement. This makes lubrication of the pallets unnecessary and thereby eliminates one of the shortcomings of the traditional lever escapement.

In 1993, Omega purchased the patent for the Co-Axial escapement from English master watchmaker and inventor George Daniels.

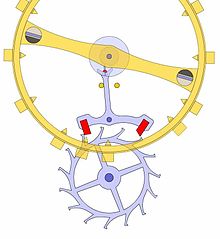

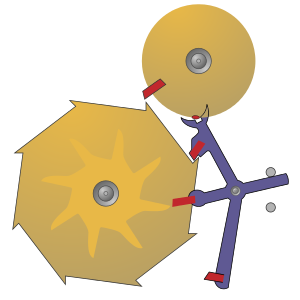

The Co-Axial escapement has two escape wheels mounted together to release the torque from the main spring. Because there are two wheels working in conjunction with added jewels, there is less friction. No longer are there two jewels sliding along the teeth of a single wheel, but now are three that just catch the edge of the teeth on two wheels. This means less friction in the escapement, thus, longer periods between services.

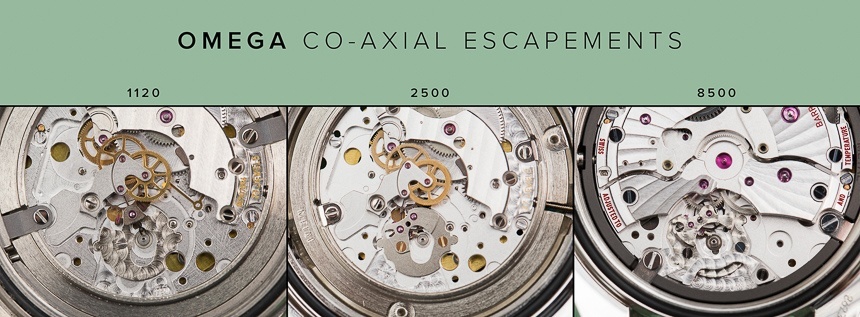

The Omega Caliber 2500 was developed by Omega in the 1990s.The Co-Axial Escapement was the first practical new mechanical watch escapement invented for mass market in 250 years. Omega began work to fit the Co-Axial Escapement to their Cal 1120 movement. The 1120 was basically a decorated version of the reliable Eta 2892-A2 movement. Omega spent the next six years developing and improving the movement to fit and utilize the larger escapement.

The components in the OMEGA Co-Axial escapement that equipped that movement differed considerably from those of the Swiss lever escapement, which had long been the industry’s mainstay. The Co-Axial escapement consists of a balance roller carrying a pallet and an impulse pin, an anchor with three pallets, and a three-level coaxial escapement wheel comprising the co-axial wheel, the co-axial pinion and the transmission pinion, with which it is connected to the intermediary wheel and the gear train.

In 1999 Omega released their first watches to the public with the Omega Cal. 2500.

The Omega 8500 Caliber family was developed in-house by Omega around a revised Co-Axial escapement to fully optimize its potential. The Co-Axial escapement is 13% larger and more efficient in the larger space.. It gets its power from twin mainspring barrels. The barrels are DLC (Diamond-like carbon) coated inside to reduce friction and have been tested to simulate over 10 years of use with little wear effect to the DLC. Sixty manual rotations of the crown fully winds both mainsprings. The “hand-wound” barrel without slip clutch is wound first, then the “automatic” barrel with slip clutch. The hand wound barrel with slightly more torque unwinds first until the automatic barrel quickly jumps in to jointly power the escapement. The bi-directional winding rotor has been redesigned to make it so efficient that it winds with the slightest wrist motion and is almost inaudible. The movement is decorated with a beautiful “Cotes de Geneve en Arabesque”.

Other improvements include: 14 leaf meshing pinion versus 8 leaf on the 2500, Nivarox Anachon balance Spring, Zircon Oxide rotor pivot jewels, improved Nivachoc shock absorber, and massive transverse balance bridge. Since 2011 the 8500/8501 have been equipped with the more stable silicon Si14 balance springs. The older versions will be gradually upgraded to Si14 balance springs at service.

With the 8500 calibers,Omega developed everything around the Co-Axial escapement instead of making the Co-Axial work with existing movements. Omega first designed the optimal Co-Axial and only then the rest of the movement. The result of this is that the Co-Axial escapement in the 8500, besides from also being larger, is actually different from the previous Co-Axials in a variety of ways.

The free-sprung balance is far, far nearer to the mathematical ideal as it does not have a regulator interfering with the spring. This helps with all forms of stability, including, of course, positional stability.

The escapement is in contact with the balance for a far shorter period allowing more of the balance’s swing to be free of interference, once again far closer to the mathematical ideal. (this, of course, can also reduce the effect of position).

Wear on the contact surfaces of the escapement has been almost entirely eliminated.