In this week’s comparison, we’ll be taking a look at the differences between date mechanisms and escapements in Rolex and Omega watches.

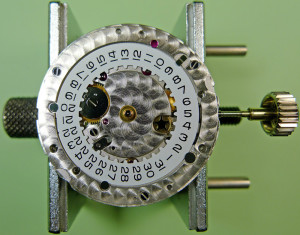

First up, let’s look at the date mechanisms. Specifically, we’ll be focusing on the Omega Co-Axial and the Rolex 3035.

Omega Date

The Omega uses an ETA type date that has been around for many years. It is simple, sturdy and works very well.

It’s also very easy to service, has no hidden springs to cause trouble and is one of my favorites to repair.

The Omega date is the essence of simplicity and is well thought out, meaning there are no hidden dangers for the watchmaker – and the simple quickset also is a big bonus.

Rolex Date

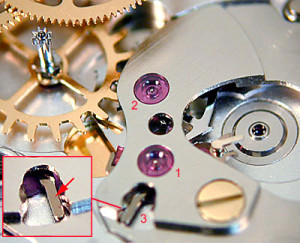

The Rolex, on the other hand, works well, but is a little more complex. It has a few tricky levers and jewels to deal with that make repairing it slightly more difficult.

The Rolex date is also well designed, and works fine with no major issues. However, you do need to be careful with the small jewel that is loose on the underside of the date trip wheel.

This one has a lever and spring attachment and takes a bit of practice to oil properly without losing anything. The date normally snaps over properly, but it also has more moving parts to deal with.

Escapement

In the same two watches, let’s look at the escapement, which is essentially the heart of the movement.

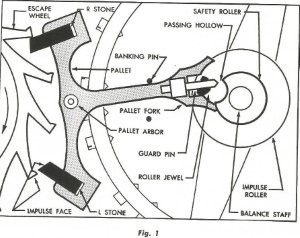

Standard Level Escapement

Considering the escapement as a unit, it can be seen that the escape wheel supplies the power, whereas the pallet transfers the rotary motion of the escape wheel into a back and forth motion of the pallet.

The pallet in turn imparts motion to the jewel pin (roller jewel) which causes a vibrating motion of the balance wheel.

Co-Axial Escapement

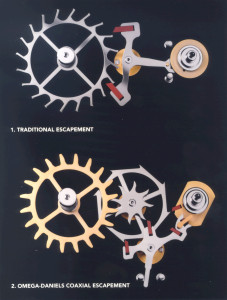

Omega launched the first Co-Axial mechanical movement in 1999. The components in the Omega Co-Axial Escapement that equipped the movement differed considerably from those of the Swiss lever escapement, which was the industry’s mainstay.

The Co-Axial escapement consists of a balance roller carrying a pallet and an impulse pin, an anchor with three pallets and a three-level coaxial escapement wheel (comprising the co-axial wheel, the co-axial pinion and the transmission pinion).

My Conclusion

The Rolex as shown uses the tried and true lever escapement that has been around for more that 100 years. It has been tested in virtually every type of watch movement and has proven itself to be sound and a true workhorse of the watch industry.

In recent years, Omega has chosen to go with the recently developed Co-Axial escapement. I have not done nearly as many watches that use this design, since it is relatively new and these watches are just starting to show up for routine service. What I can tell you is that the Co-Axial escapement works well and I have not had any difficulty with it so far.

What I can’t tell you is how well it is going to run in the future after years of wear. In my opinion, Omega was looking for some sort of marketing approach that would set itself apart from its main rival, Rolex. They have committed themselves to this new design in all of their high-end watches as a way of trying to keep and expand their market share. As of now, I am not a big fan of this new escapement, and here’s why:

I try to evaluate watch movements from the prospective of a watchmaker as to how easily they can be repaired. Sometimes engineers get in a room and decide to develop a “better mousetrap” in order to satisfy the latest marketing strategy set up by their employers.

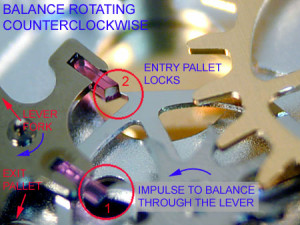

The Co-Axial is a new and unique design, but it is going to be virtually impossible to make any repairs to these small and precise pallet stones in the future.

To give a quick story, one month I had to adjust the pallet stones in two Rolex 3135 movements. This is very rare to have escapement trouble in a watch like this, but it happens.

Trying to adjust a pallet stone in any watch is the single most difficult repair that any watchmaker can attempt. Try to imagine moving the stone in or out just about the thickness of a piece of paper — that is how precise the adjustment needs to be in the pallet in order for it to work correctly.

The pallet stones are held in place by shellac, which needs to be heated in order to move the stones. The pallet is held in a special tool, then heated over an alcohol lamp flame until the shellac softens. Then you have a few seconds to push or pull the stone (without losing it) before the shellac hardens.

On the last repair, I did this adjustment 10 separate times before I got it right. On the Co-Axial escapement, you have twice the number of stones to deal with. I don’t even want to think about trying to adjust them! In the future, if there is a problem with the wheels or levers, I would just try and replace them instead of repair them, so the cost is going to be higher.

This is a long-winded answer to the question, but my vote is a big thumbs up for the standard escapement in the Rolex.