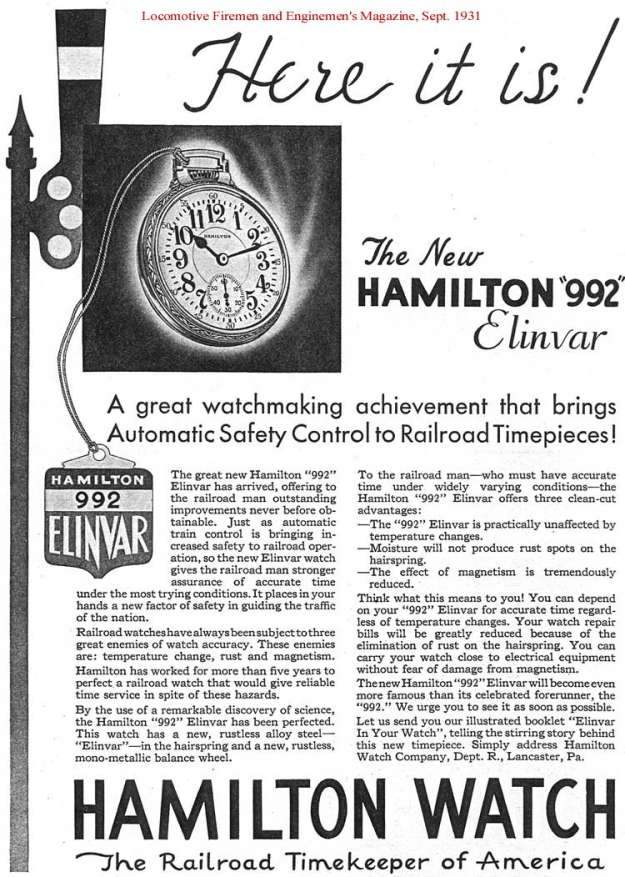

Back when trains were first connecting America’s coasts, a railroad worker’s watch would be worn through some tough conditions.

First, it must endure temperature and humidity changes, as well as changes in magnetic fields.

That’s not to mention regular wear and tear a watch will be presented while working a long day on the railroad.

When railroad watches were inspected, they were to run within 30 seconds accuracy.

The Elinvar metal alloy set out to help protect watches from those conditions.

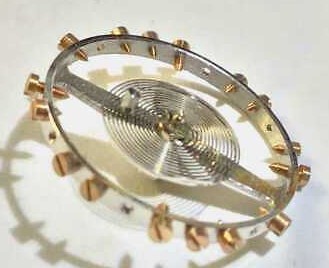

Introduced as the 922 Elinvar Watch Movement, the device differs from the 992 Movement by replacing the conventional steel hairspring with a mono-metallic balance wheel and an Elinvar hairspring.

The movement helps against declining elasticity that steel hairsprings tend to see when temperatures rise, making them weaker. This means a watch would run slowly when warm and faster when cool.

As trains need to run on a precise time schedule, it only makes sense that a railroad worker’s watch must be exact.

The time error can be made up by using a bimetallic balance to help a watch keep steady time when heated up or cooled down.

The Elinvar development meant a metal which would be automatically temperature compensated, so that correct time would be kept regardless of temperature changes.

The Elinvar movement also had other favorable aspects.

Because it was made from nickel-steel alloys, it was rust-proof, something other steel hairsprings did not have the benefit of being. Watches with the Elinvar also help against magnetization.

In short, the 922 Elinvar eliminates time changes stemming from damaged mainsprings to keep the watch maintained to its factory standards.