One of the most important parts of any mechanical watch is a Cannon Pinion.

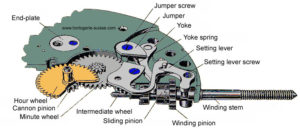

The cannon pinion is the heart of the motion works. This piece is what translates the movement of the train wheels into the timekeeping display on the dial side. It is attached to the center wheel by friction fit and it is the post that the minute hand is set on.

How to remove Cannon Pinion for service

One major problem with any mechanical watch is when a cannon pinion is too loose. Symptoms of a loose cannon pinion are a running watch that seems to lose lots of time during a normal day. A loose cannon pinion on a date watch is a bigger problem. On a date watch, it may run well, but when it gets close to midnight and the date changes, the hands will stop advancing. The watch will continue to run, the hands just won’t move. Keep in mind that when the date is changing on a mechanical watch, there are lots of wheels that need to engage and have to push the date ring past a click spring. If the cannon pinion is loose, there is just not enough friction to keep things tight to advance the date.

How to tighten a Cannon Pinion

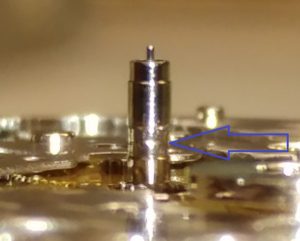

There are a few different methods used to tighten a loose cannon pinion. You can use a staking set and gently tap a punch at the small indentation on a cannon pinion. There are special tools sold that will help tighten the pinion. I have used the simplest method possible all these years. I gently squeeze the pinion with a special set of cutters. Simple and to the point. You need to insert a metal rod of some kind through the pinion (use an old oiler), this will help you from squeezing too hard. You need to find the small indentations on either side of the pinion, then gently apply some pressure with your cutters. Then put the pinion back in the watch and see how it “feels”. You may need to try it 2-3 times until it is “just right.” This is one of the areas where you can’t measure how much pressure to apply, it is just something that you learn after lots of practice. We have a simple saying around the shop: “A little bit more, a little bit more, oops too much.” You want to avoid getting to the “oops, too much” stage, but that comes with practice.

ETA type of Center Wheel/Cannon Pinion

There is another type of Cannon Pinion that is commonly used in some watches. This type of pinion does not friction onto the center wheel. The friction comes from the center post that is attached to a lower wheel. The two bars attach to the bottom of the pinion making the friction. This wheel is used on just about all ETA movements, it works quite well. The only problem is there is no real way to tighten it if it becomes worn. If the two friction points are not oiled properly, it will cause the bottom wheel to wear and loosen. The only repair is replacement.

CHARLEY PHOTO OF THE WEEK: Charley and Tom took a few days off for Thanksgiving and are slowly getting back into the watch repair groove this week.